Prolyte CCS6 Spigots

Detail

When the Prolyte Group designed the original Conical Coupling System (CCS), it constituted a huge step forward in the development of truss systems. Even today, the now much-copied Conical Coupling System is unrivalled in efficiency, strength and ease of assembly. The innovative Conical Coupling System has many advantages over other types of connection systems and has gained a worldwide regulation for excellence and efficiency. The Conical Coupling System makes the assembly of your truss system safe, fast and easy, yet rigid and strong.

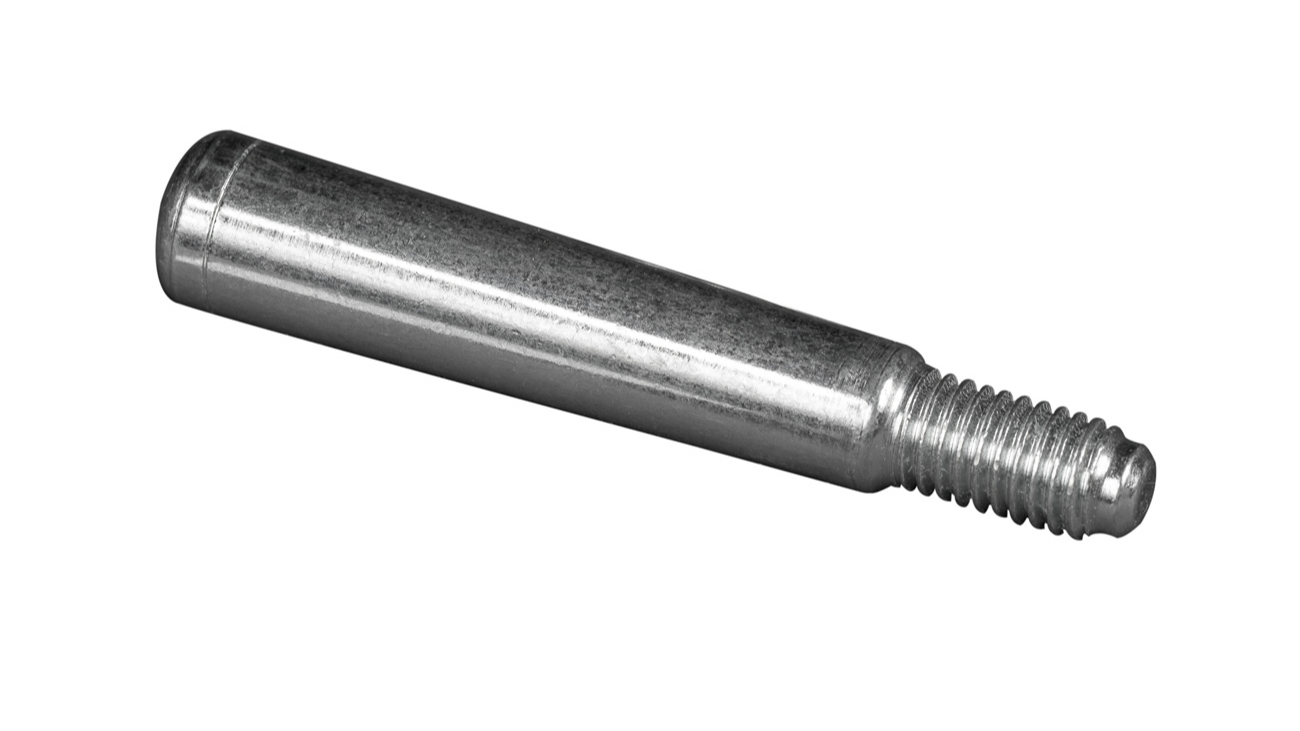

Spigot pins are used to secure the conical coupler in its position. Like the conical coupler, the spigot pins are also conical, tapered, in form. A slight tap with a copper hammer secures them in position. You can purchase them separately or in unison with the corresponding securement fitting. Below is a helpful list to assist you in identifying the different spigots Prolyte provides. If you have any questions, please contact a branch nearest you.

- CCS6-603: The standard Prolyte spigot (length 67 mm). Utilises the CCS6-605 R-spring.

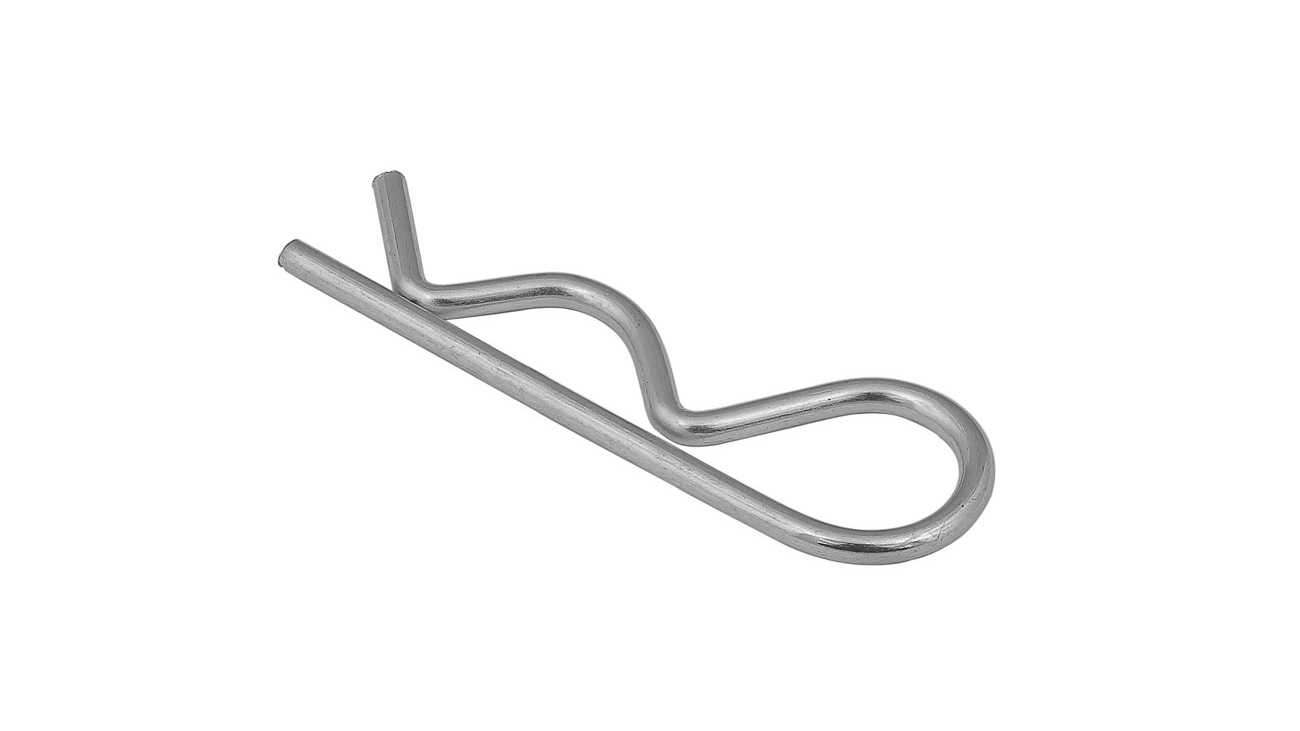

- CCS6-605: R-spring. Used in conjunction with the CCS6-603 and CCS6-607.

- CCS6-607: Spigot with reduced length (length 65 mm). Utilises the CCS6-605 R-spring.

- CCS6-604: Threaded spigot (length 66 mm). Used for permanent indoor installations. Utilises the BM-M8-SN self-locking M8 nut.

- CCS6-604-RF: Rust-free threaded spigot (length 66 mm). Used for permanent outdoor installations. Utilises the BM-M8-SN/RF rust-free self-locking M8 nut.

- BM-M8-SN: Self-locking M8 nut. Used in conjunction with CCS6-604 threaded spigot.

- BM-M8-SN/RF: Rust-free self-locking M8 nut. Used in conjunction with CCS6-604-RF rust-free threaded spigot.

inspection / Testing

With over 40 years experience in maintaining it’s own rental fleet , Rigging Services offers the same regime of inspection and testing in compliance with the LOLER regulations to it’s clients. Rigging Services engineers are all LEEA qualified as testers , inspectors and verifiers on lifting & rigging equipment. Using its own bespoke software & hand held devices Rigging Services offers a real-time internet based reporting portal of onsite inspections and testing. Use our guest user name and password to log into our unique Onsite Online service and see what we mean. This cost effective , paperless solution allows legal compliance and peace of mind.